Price 500000.0 आईएनआर/ टुकड़ा

Specification

- फेज

- Single

- शेप

- Square

- प्रॉडक्ट टाइप

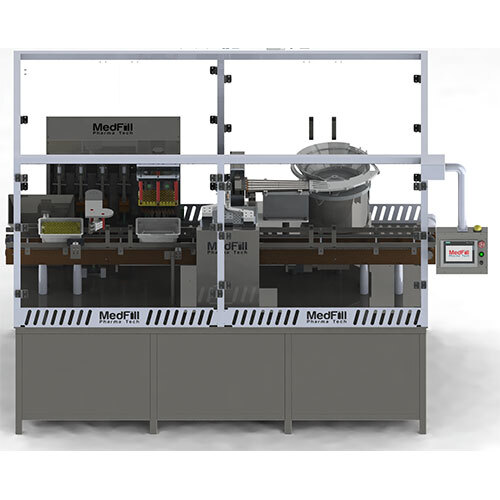

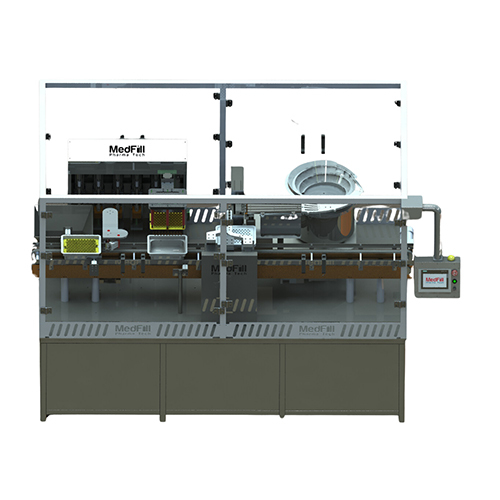

- SEMI AUTOMATIC PFS MACHINE

- मटेरियल

- कम्प्यूटरीकृत

- ऑटोमेटिक

- टच स्क्रीन

- वोल्टेज

- वोल्ट (v)

- रंग

- Silver

- वारंटी

- 1 Year

Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

- नमूना उपलब्ध

- No

- मुख्य निर्यात बाजार

- मुख्य घरेलू बाज़ार

- प्रमाणपत्र

- No

About

Our SemiAutomatic PreFilled Syringe PFS Filling Stoppering Machine is a highprecision solution tailored for small to mediumscale pharmaceutical production It combines flexibility accuracy and robust design meeting the needs of injectable manufacturing with operatorfriendly handling

Key Features

Filling Options

Rotary Syringe Pump Ideal for highviscosity liquids with consistent and robust performance

Peristaltic Pump Suitable for sterile and clean filling quick tubing changeover and compatible with smallvolume dosing

Filling System

5Head highaccuracy pump configuration customizable as per need

Servodriven filling for superior accuracy and repeatability

Filling range 02ml to 5ml with 1 accuracy

Stoppering System

Advanced Vacuum Chamber Technology for accurate and gentle stopper insertion

Nitrogen Purging feature prior to stoppering for enhanced product stability and reduced oxidation

Syringe Handling

Designed for nested syringes with easy manual loading and unloading

Ensures minimal human intervention in the critical zone

Control System

Intuitive HMI System for userfriendly operation and parameter control

Alarm notifications for critical faults and process safety

ServoDriven Mechanism

XY Servo Table for precise syringe positioning

Adjustable height mechanism for different syringe formats

Compliance Safety

Designed as per cGMP standards

Can be configured with 21 CFR Part 11 compliance for data integrity and audit trails

Custom Integration Options

Optional integration with labeling and Plunging machinery or batch recording systems

Formatfree design for quick changeover and minimal downtime

Frequently Asked Questions FAQs

What kind of filling options are available in this machine

Answer This machine supports two types of filling mechanisms

Rotary Syringe Pump Suitable for highviscosity liquids and provides mechanical robustness

Peristaltic Pump Ideal for sterile applications allows easy tubing changeover and minimizes product contact

How does the vacuum chamberbased stoppering work

AnswerIn vacuum chamberbased stoppering nested syringes are placed inside a sealed chamber A vacuum is applied to remove air and then the rubber stopper is gently placed on top of each syringe This technique ensures consistent stopper insertion without air entrapment and is especially suitable for aseptic and nitrogenpurged processes

What is the difference between a SemiAutomatic and a Fully Automatic Pipe InOut Type PFS Machine

AnswerSemiAutomatic PFS Machine Requires manual loading and unloading of nested syringes Ideal for small to mediumscale production or RD setups

Fully Automatic Pipe InOut Type PFS Machine Features automatic handling of nests filling stoppering and movement across stations without operator intervention Suitable for largescale and highspeed production lines

Which stoppering method is better Pipe InOut or Vacuum Chamberbased How should I choose

AnswerVacuum ChamberBased Stoppering is recommended for highprecision aseptic environments and nitrogenpurged applications It ensures no air bubble entrapment

Pipe InOut Type Stoppering is a costeffective solution for higher speed requirements but may not offer the same level of air removal or uniformity

Selection Tip Choose Vacuum Chamber for highquality and injectablecritical products Choose Pipe InOut for costeffective highthroughput lines where absolute vacuum is not required

Which filling option is better Peristaltic or Rotary Syringe

Answer Peristaltic Pump Preferred for sterile processes lowvolume fills and easy changeover between products Minimal risk of contamination since the liquid only contacts the tubing

Rotary Syringe Pump Offers precise volumetric filling and is better for highviscosity liquids but requires more maintenance and cleaning

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in पीएफएस मशीन Category

पूरी तरह से स्वचालित प्रकार की पीएफएस मशीन

माप की इकाई : यूनिट/यूनिट

वोल्टेज : 415 वोल्ट (v)

कंट्रोल सिस्टम : Human Machine Interface

मूल्य की इकाई : यूनिट/यूनिट

क्षमता : 24000 शीशियाँ/घंटा पीसी/घंटा

फेज : तीन

जांच भेजें

जांच भेजें

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese