Price 500000.0 आईएनआर/ टुकड़ा

Specification

- फेज

- Single

- व्यास

- मिलीमीटर (mm)

- शेप

- Rectangle

- प्रॉडक्ट टाइप

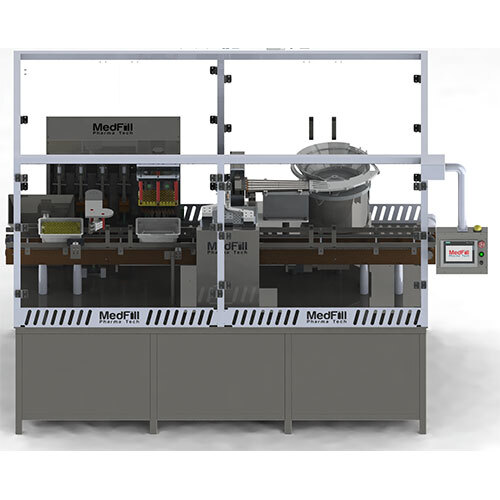

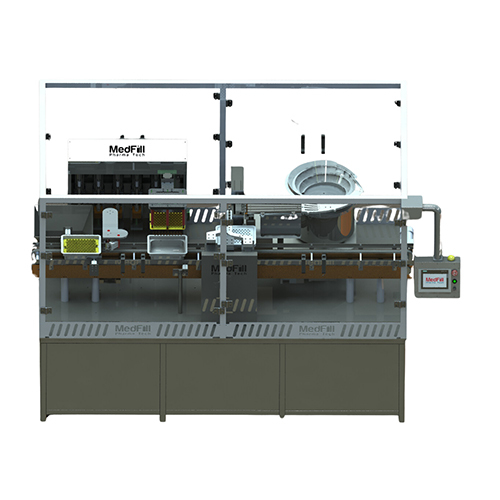

- FULLY AUTOMATIC PFS MACHINE

- सामान्य उपयोग

- YES

- मटेरियल

- टाइप करें

- , ,

- क्षमता

- मिलीलीटर (ml)

- वजन (किग्रा)

- टन

- कम्प्यूटरीकृत

- ऑटोमेटिक

- टच स्क्रीन

- कंट्रोल सिस्टम

- सतह का उपचार

- सहनशीलता

- मिलीमीटर (mm)

- चित्रकारी

- वोल्टेज

- वोल्ट (v)

- आयाम (एल* डब्ल्यू* एच)

- मिलीमीटर (mm)

- फ़ीचर

- वारंटी

- 1 Year

Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

- नमूना उपलब्ध

- No

- मुख्य निर्यात बाजार

- मुख्य घरेलू बाज़ार

About

Manual Bucket Placement Optional Can be Automated Later

Operator places the bucket at the entry conveyor Future scope Visionguided robotic bucket placement

Fully Automatic Paper Removal

A robotic arm preferably 4 or 6axis equipped with a vacuum gripper or soft suction pad

Identifies paper location via vision sensor or fixed positioning Picks and removes the protective paper sheet from the syringe trayTransfers and discards it in a designated bin

This eliminates human involvement at the Glow Pot Location

Automated Tray Handling

Pickandplace system or SCARA robot picks the syringe tray from the bucket and places it on the filling table

Stoppering with Pipe InOut Technology

5track vibrator bowl feeding system for stoppers

Pipe InOut Stoppering system places plungers accurately into syringes

HighAccuracy Filling

Peristaltic pumpsRotary Syringe controlled by servo drives perform the filling operation with 1 accuracy

Additional Automation If applicable

Vision Inspection plunger presence fill level cosmetic defects

Online Rejection System

Tray Rearrangement and Exit Conveyor

Benefits of Full Automation

Zero human touch after bucket placement

Improved batch consistency and compliance

Enhanced sterility and GMP validation

Reduced operator fatigue and labor dependency

Shorter cycle time and higher productivity

Frequently Asked Questions

What kind of stoppering systems do you offer

We offer Pick and Place Type and Vacuum Chamber Type stoppering systems based on the specific requirements of your production process

Can the machine be configured with LF RABS or an Isolator

Yes the machine can be configured with Laminar Flow LF Restricted Access Barrier Systems RABS or an Isolator depending on your operational and regulatory needs

What functions are covered in the fully automatic version

The fully automatic version includes nest paper removal filling and stoppering all managed through advanced robotic motion This automation minimizes human intervention and maximizes efficiency

What is the difference between the semiautomatic and fully automatic versions

In the semiautomatic version after the filling process the operator manually places the nest in the vacuum chamber for stoppering In the fully automatic version all processes including nest handling filling and stoppering are fully automated and controlled by robotic systems

What kind of filling methods do you use

We use highly accurate Peristaltic Pump or Rotary Syringe filling methods selected based on the customers User Requirement Specification URS

What is the filling accuracy of the machine

We provide a filling accuracy of 1 of the filled volume For example if you are filling 2ml the variation will be within 002ml

What is the filling volume range the machine can handle

The machine is designed to handle various filling volumes customizable based on specific production needs

How many heads are available and what is the production speed

The machine can be configured with 2 5 or 10 heads depending on your production requirements with speeds ranging from 4500 to 10000 syringes per hour

What types of syringes can the machine fill

The machine is versatile and can fill a wide range of prefilled syringe types including both standard and customdesigned syringes

Can the machine be integrated with SCADA systems

Yes the machine supports integration with SCADA systems and is fully compliant with 21 CFR Part 11 ensuring adherence to global regulatory standards

What kind of maintenance is required for the machine

Routine maintenance includes regular checks of moving parts calibration of filling mechanisms and cleaning We recommend scheduled servicing by qualified technicians to ensure optimal performance

Is there a warranty for the PFS machine

Yes the machine comes with a comprehensive warranty which covers parts and labour for a specified period providing longterm reliability and peace of mind

Can the machine be customized to meet specific production requirements

Yes we offer a range of customization options to meet your specific needs including different stoppering systems filling methods and automation levels

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in पीएफएस मशीन Category

पूरी तरह से स्वचालित प्रकार की पीएफएस मशीन

मूल्य की इकाई : यूनिट/यूनिट

ऑटोमेटिक : Yes

वोल्टेज : 415 वोल्ट (v)

न्यूनतम आदेश मात्रा : 1

मूल्य या मूल्य सीमा : आईएनआर

फ़ीचर : High Efficiency

जांच भेजें

जांच भेजें

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese