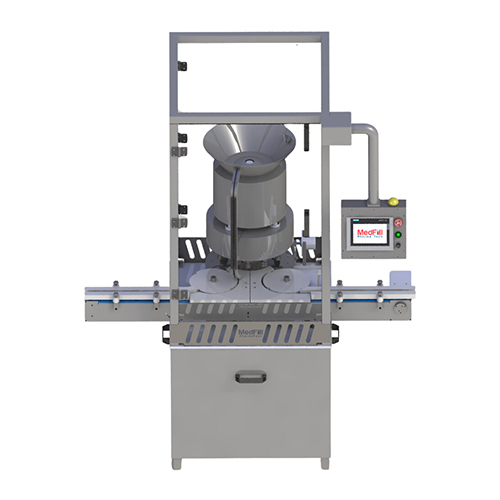

Alluminium Cap Sealing Machine

Price 500000.0 INR/ Piece

Alluminium Cap Sealing Machine Specification

- Driven Type

- Electric

- Dimension (L*W*H)

- 1300X800 Millimeter (mm)

- Condition

- New

- Application

- Industrial

- Voltage

- 230 Volt (v)

- Packaging Material

- PLASTIC

- Sealing Length

- 1500

- Weight

- 15000 Kilograms (kg)

- Automation Grade

- Automatic

- Sealing Speed

- 350/MIN

- Filling Capacity

- 100 Milliliter (ML)

- Accuracy

- 100 %

- Packaging Speed

- 350 Sets/Min

- Production Capacity

- 24000 Vial/Hour Pcs/hr

- Seals Type

- ALUMINIUM

- Type

- VIAL CAP SEALING MACHINE

- Color

- Silver

- Sealing Type

- ALUMINIUM

- Power

- 240 Watt (w)

- Contact Load

- 1000

Alluminium Cap Sealing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 1 Piece Per Month

- Delivery Time

- 13 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Alluminium Cap Sealing Machine

Our highspeed Cap Sealing Machine seals up to 24000 vials per hour with Pressure Rejection and auto height adjustment for quick changeovers It can be equipped with 21 CFR Part 11 SCADA ensuring precise consistent sealing for various vial sizes based on your requirements

SPECIAL FEATURES

Up to 24000 vialshour

GMP COMPLANCE 21CFR PART 11 SCADA SYSTEM

Automatic Height Adjustment based on Vials

Online Pressure Rejection System and Vision Camera Based Sealing Rejection System

SAMPELING REJECTION

Adjustable Height of Conveyor from 900mm to 950mm

Can be Equipped with oCARBS cCARBS or Isolator

The MedFill Cap Sealing Machine is an advanced solution designed to meet diverse production needs in the pharmaceutical industry offering precision speed and flexibility Available in configurations of 2 4 6 8 and 12 heads this machine can be tailored to match your specific speed requirements sealing up to 24000 vials per hour

Key Features

Pressure Rejection System The machine includes a Pressure Rejection system that ensures each cap is applied with the correct torque If a cap is improperly sealed the vial is automatically rejected maintaining the integrity and quality of your products

Machine Auto Up and Down Facility To further enhance efficiency the machine can be equipped with an Auto Up and Down feature This system automatically adjusts the machine height based on the selected recipe or vial size significantly reducing changeover time and ensuring consistent performance across different product runs

No Cap or Different Colour Cap Rejection The machine is designed to automatically reject any vial that is missing a cap or has a cap of a different color preventing defective products from reaching the market and ensuring uniformity in your production line

Quick Changeover Time With features like Auto Up and Down and precise calibration systems the machine minimizes product changeover time enabling swift transitions between different production batches and maximizing productivity

21 CFR Part 11 Compliance For facilities that require stringent regulatory adherence the Cap Sealing Machine can be equipped with a SCADA system that complies with 21 CFR Part 11 This feature ensures secure traceable electronic records and supports regulatory audits

No Cap in Bowl Machine Stop To prevent potential issues during operation the machine includes a safety feature that halts the production line if no caps are detected in the bowl allowing operators to address the issue promptly and avoid downtime

Specification

Supply Voltage 230VAC 1PHASE 50HZ

Power Requirement 3 HP

Speed 24000 VialHour Based on Number of Head

Vial Size 1ml to 100ml

No Of Head 2 4 6 812 or 16

Cap Size 13mm 20mm 32mm

Benefits

UserFriendly Operation The machines interface is designed for ease of use allowing operators to quickly learn and manage the system with minimal training

Durable Construction Built with highquality GMPcompliant materials the machine is durable and easy to clean ensuring longterm reliability and compliance with industry standards

Customizable Options Whether you need to seal small vials or larger containers the machine can be customized to meet your specific requirements offering flexibility and adaptability for various production needs

FAQs of Alluminium Cap Sealing Machine

Q What is the production capacity of the Aluminium Cap Sealing Machine

A The production capacity of the machine is 24000 vials per hour

Q What is the accuracy level of the machine

A The machine has an accuracy level of 100

Q What is the voltage requirement for operating this machine

A The machine operates at 230 volts

Q Is the machine suitable for industrial applications

A Yes the machine is designed for industrial use

Q What is the automation grade of the machine

A The machine has an automation grade of automatic

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese